General-purposed TIF Operation panel (with software components built-in)

World-top class TIF Multi-axis machine controller panel (with standard software components built-in)

Product outline

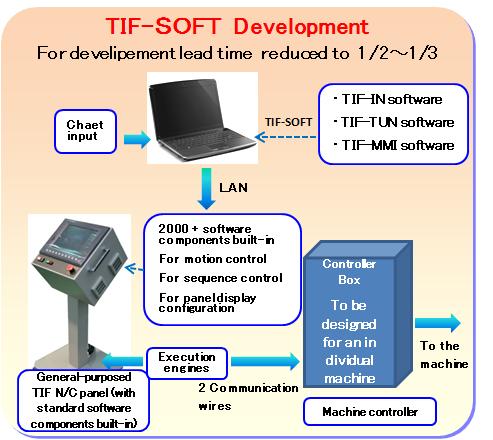

●2000 plus software parts in C-language are built in the operator panel. The software linkage is exercised by TIF-SOFT in the PC.

●Once the time chart or flow chart being entered into the TIF-SOFT Development tool, all necessary software parts are automatically called for NC motor starts and stops, inter-axial simultaneous control. Sequence ON/OFF, and executes tuning and configuration layout of the operator panel.

●For new application areas of NC machines other than of Opton-brand, the sales in industrial market is scheduled to start in direct route, through distributors and/or controller builders upon our business feasibility is completed shortly.

What is the TIF operator Panel (with standard software components built-in)

The TIF Operator Panel harbors varieties of software components that have been created and refined through the years-long experience of building software know-how with Opton's original machines of pipe benders, 3D profilers, Hydro-formers, etc.

The TIF operator Panel is the general-purposed NC controller (or varieties-of-engines-built-in hardware) for industrial machines.

No NC programming know-how is needed by an operator as the oputimum software engines are pulled out for automatic creation of necessary control programming simply by putting the data of time-chart or flow-chart in the TIF-IN (the engine to create controlling programming).

The screen layout of data-entry, operation switches and lightening are configured by activating of TIF-MIMI (the engine to configure the operation panel display). For servo tuning of the machine, TIF-TUN (Servo tuning engine) executes high-precision type of performance.

TIF-SOFT Development Tool

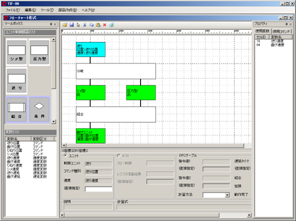

①TIF-IN(Time chart & flow chart creation engine)

By entering the flow-chart or time-chart, the programming is created by the properly selected engines

- Creation of unit-controller parameters

Parameters settings are executed for the software components which control servo axis, simultaneous motion, cylinder/servo motor and I/O. - Flow-chart programming(suitable access by software engineer)

This suites when machine motion is programmed based on the flow chart. - Time-chart programming (suitable access by mechanical engineer)

This suites when machine motion is programmed based on the time chart.

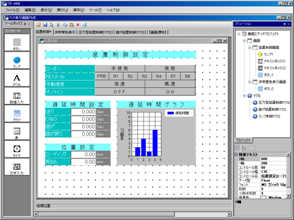

②TIF-MMI(Operation screen software)

Operation screen is built with allocation and setting of data entry, location and setting of press button switching, and lamps.

- Screen creation

Switches, lamp, data entry, numeric monitor etc are configured for screen display - Setting of indicator software components

Software component selection and setting are executed for light-on with switching ON or light-off with switching OFF - Allocation of variables of indicator software components

Variables of the components are installed.

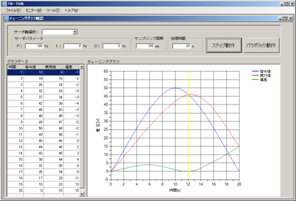

③TIF-TUN(Servo-tuning supporting software)

This works for tuning of the servo-axis.

- Auxiliary support for servo-axis tuning

- Modification of the control parameters

- Auxiliary function of debagging (Execution program monitoring)

- Variables monitoring

Features

- Opton original NC with the latest and leading-edge version The performance are fully appreciated in the markets with its installation made to all NC machines ex-Opton, in original or renewal employments.

- 2000-plus C-Language software components are built in the controller. The software linkage are executed by TIF-SOT in PC

- By entering either of time-chart of flow chart in the TIF-SOFT development tool, all necessary software components are automatically selected to execute tuning and display setting of NC motor ON/OFF, synchronous axial control of drives and sequence ON/OFF control as well.

- Upon the evaluation of reliability of the products being finally completed installed to Opton machines in a few years time, this controller is going to be put available in the market through direct, agent and/or NC manufacturers

- By configuring the display layout, relevant software linkage is automatically executed between operation and control.

- This controller is employed to all Benders, 3D Profilers, Hydro-formers ex-Opton as its original or renewal feature. The performance increases remarkably higher market reputation for easier iconization, speedy control, LAN, Failure-finding and customization.

Series

| Article | Specification |

|---|---|

| CPU | Intel ATOM |

| Memory | 512MB |

| OS | Windows XPE |

| LCD | 15inch XGA |

| Touch panel | 5-wires resistive type |

| Serial(RS-232C) | 2ports |

| USB 2.0 | 4ports |

| LAN | 2ports |

| Ambient temperature | 0℃~40℃ |

| Power consumption | 100W |

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

●This controller is employed to all Opton benders, 3D profilers and hydro-former series.

●This controller is employed to all renewed benders.

20-years old machines, now with this controller to be installed, can be refreshed to the newest version with easiest operation and highest performance currently available in the markets.

Further possible enhancement of performance is expected with collaboration of 3D profilers in line and with world-wide communication being facilitated. Extended service life may be expected as a top quality machine for another decade or even longer.