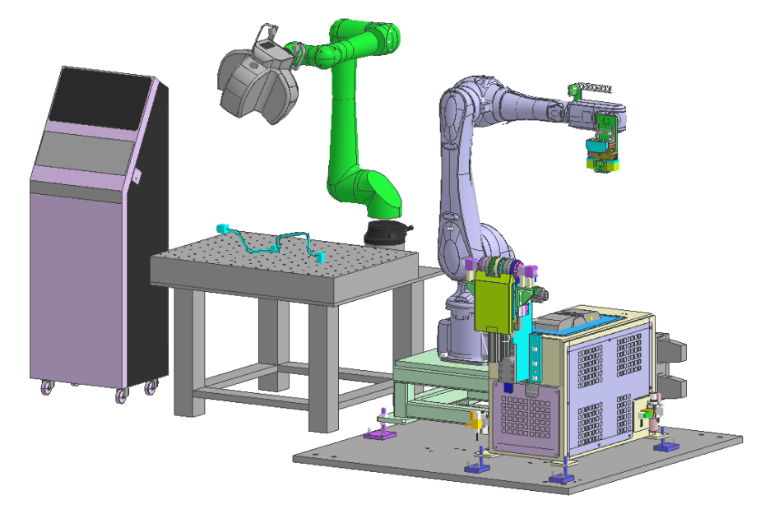

Recommended System

GW-type Robot Bender

+ Collaborative Robot Former System

From 3D CAD data, the entire process from tube feeding, processing (feeding, twisting, bending), removal, to correction is performed in the shortest time. This is a system combining the GW-type robot bender and the collaborative robot former.

System Overview

The GW-type robot bender performs the entire process from tube feeding, feeding, twisting, bending, to removal, and automatically transfers it to the collaborative robot former.

The collaborative robot former measures the processed tube with a 3D scanner and provides correction data to the GW-type robot bender if there is a discrepancy with the processing data.

This function enables high-precision processing of good products in a short time.

User Image

Companies that have previously outsourced tube bending processing but wish to perform it in-house in the future.

Companies currently performing tube bending processing manually by craftsmen but anticipating a shortage of craftsmen in the future and aiming for automation.

System Features

The GW-type robot bender automatically performs the entire process from ① tube feeding, ② feeding, twisting, bending, ③ removal, to transferring the processed tube to the collaborative robot former, realizing labor-saving through full automation.

The collaborative robot former measures the processed tube with a 3D scanner and provides correction data to the GW-type robot bender. By limiting the movement speed to below 250 mm/sec, installation of safety fences at the site becomes unnecessary, enabling collaboration between humans and robots in the manufacturing site.

By directly moving the handle of the robot’s 3D scanner part by hand and pressing the positioning button, measurement and teaching work using the direct teaching function can be performed. Even unskilled workers can perform teaching work without expertise. Compared to robot teaching work using a teaching box, this significantly reduces the workload.

Features of Each Device

GW-type Robot Bender GW-SWV-15

Reduces interference by double bending in both directions. Reduces processes, thereby lowering mass production costs.

The newly developed vertical bending method makes the bending head compact with less interference. Each side of the head can mount two sets of molds (total of 4), enabling setup-free operation.

An ideal robot bender for unmanned and FA line construction, achieving cost reduction and space-saving.

Collaborative Robot Former RF-1000

A measuring device combining a collaborative robot and a 3D scanner.

A measuring device utilizing a marker base plate that automatically corrects absolute accuracy.

Guarantees absolute accuracy by comparing the position of the mark with the position of the tube being measured.

Calls up and automatically plays back programs generated from the direct teaching function, enabling repeat measurement of the same type of workpieces.

Inquiries about Products

Please wait for a while until the form is shown.

Sorry, if you can not see the form even if you wait for a while, please contact Here.