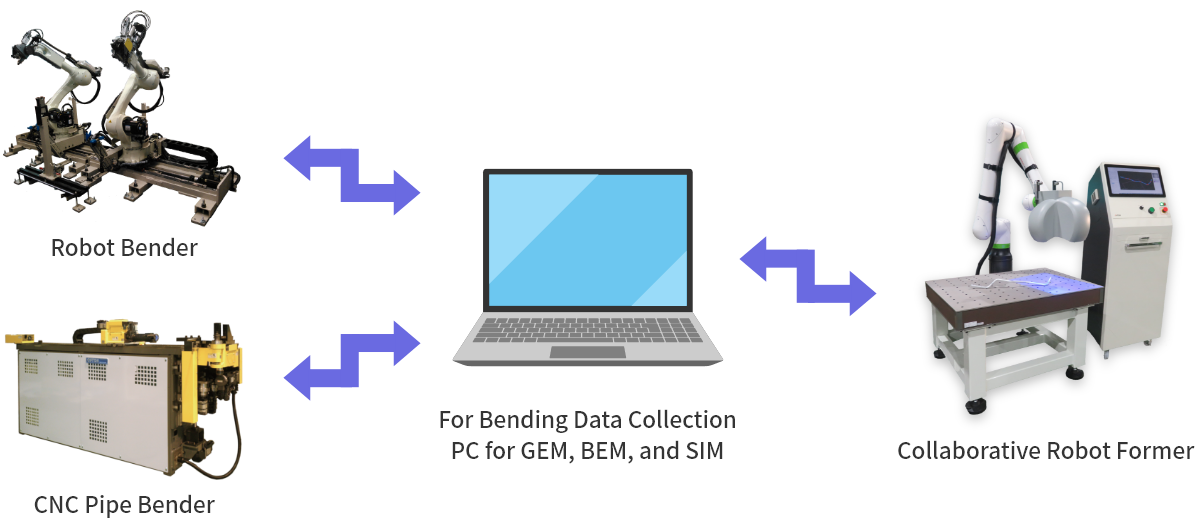

Software

By introducing CNC tube benders and robot benders, the digitalization of equipment can be advanced; furthermore, by enabling connections between each machine and PCs, and ensuring compatibility with CAD data, software products that can strongly promote FA and DX across the entire production site are introduced.

Features

We have listened to the voices from the pipe-processing site and solved their concerns with software.

GEM: A tool that can extract bending intersection coordinates from 3D CAD data.

BEM: Makes it possible to create bending operation data regardless of location.

BEM: Also effective for backing up ever-increasing processing data.

SIM: Simulation software that reduces tube waste during prototyping caused by interference during bending operations.

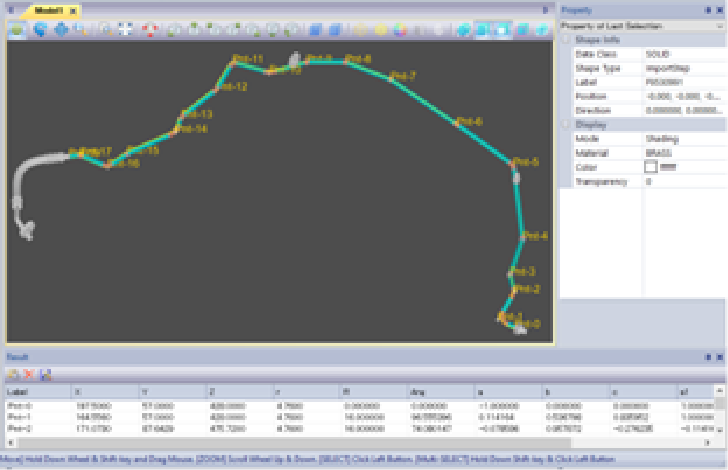

GEM

GEM

Extracts the center intersection coordinates of straight tube sections from 3D CAD data.

Traditionally, center intersection coordinates were obtained by a person from paper drawings to create machining data. By loading 3D tube outline data into the GEM software, it generates the tube’s centerline and dimension lines such as flanges, extracts the tube’s center intersection coordinate data in CSV format, and then by importing that into BEM, bending processing data can be created.

BEM

BEM

Enables creation, centralized management, aggregation, search of bending processing data, transfer from PC to tube bender, and backup of bending processing data from the tube bender to the PC.

- Enables centralized management, aggregation, search, and production instructions for the product’s bending data.

- Transfer of bending processing data from PC to CNC tube bender, and copying (backup) of bending processing data from CNC tube bender to PC is possible.

Data generated with the GEM software can be imported into the BEM software and transferred to the tube bender as bending processing data.

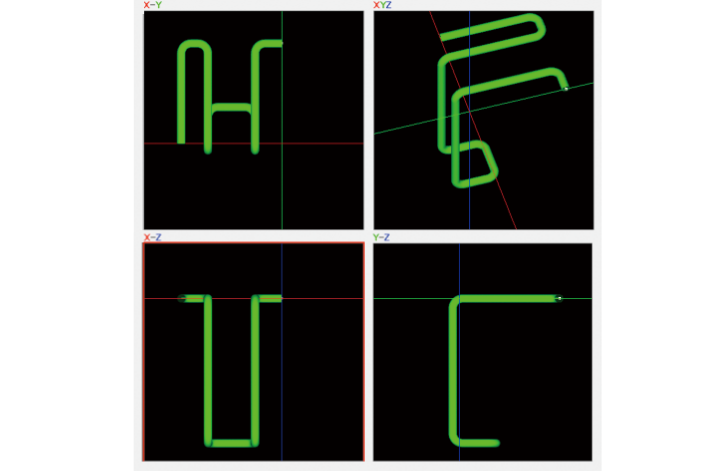

SIM

SIM

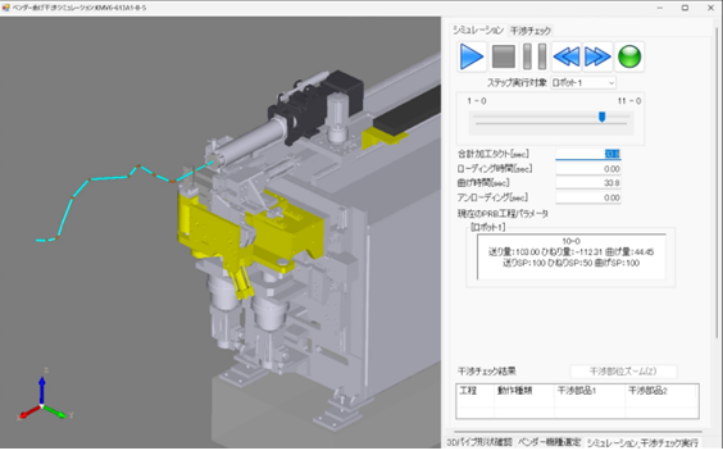

In a 3D model of a tube bender and a virtual space that realistically reproduces the installation environment, interference checks during tubebending and machining time can be simulated. This reduces time and material waste during the prototyping phase of bending.

Displays the bending state of the tube bender and workpiece, enabling interference checks. You can freely control pause, reverse playback, rotate the field of view, zoom in/out, and reposition. The created machining data can be imported directly into Opton tube benders.

SIM Tool Features

- When bending data is input into the SIM (simulation) software, the bending processing takt time and interference with the machine body can be checked.

- You can create and save 3D models of the CNC tube bender machine body and machining molds, create a virtual tube bender (processing cell) on a computer, and perform 3D bending simulation using bending processing data (RPB data).

- Displays the bending state of the tube bender and workpiece, enabling interference checks.

- Pause, reverse playback, rotate view, zoom, and reposition freely available.

- You can also measure processing cycle time via simulation.

- Created machining data can be transferred as is to Opton-made CNC tube benders.

Inquiries about Products

Please wait for a while until the form is shown.

Sorry, if you can not see the form even if you wait for a while, please contact Here.