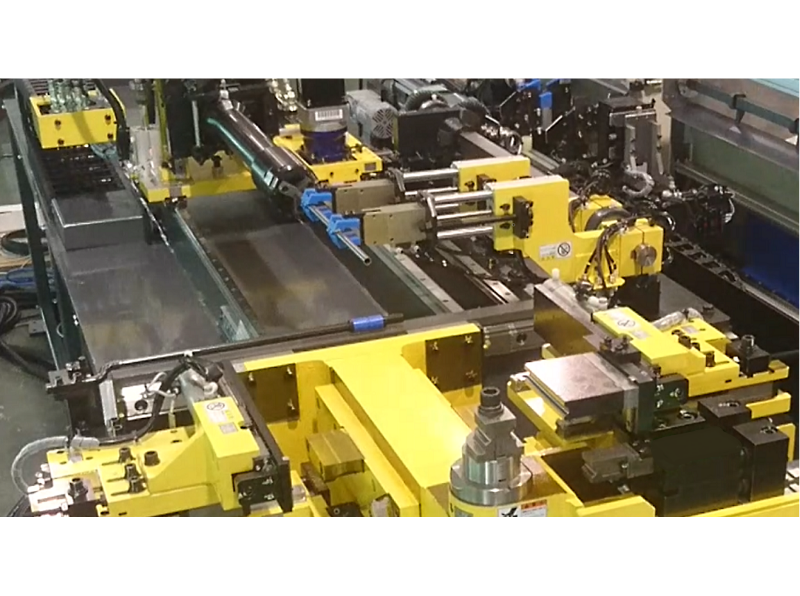

Peripheral Equipment

Introducing peripheral equipment that, when combined with CNC tube benders or robot benders, promotes labor reduction, FA automation, and DX transformation in manufacturing sites.

Loader

Loader

Available feeding methods according to manufacturing conditions:

- Front feed

- Side feed

- Offset feed

- Rear feed

- Robot feed

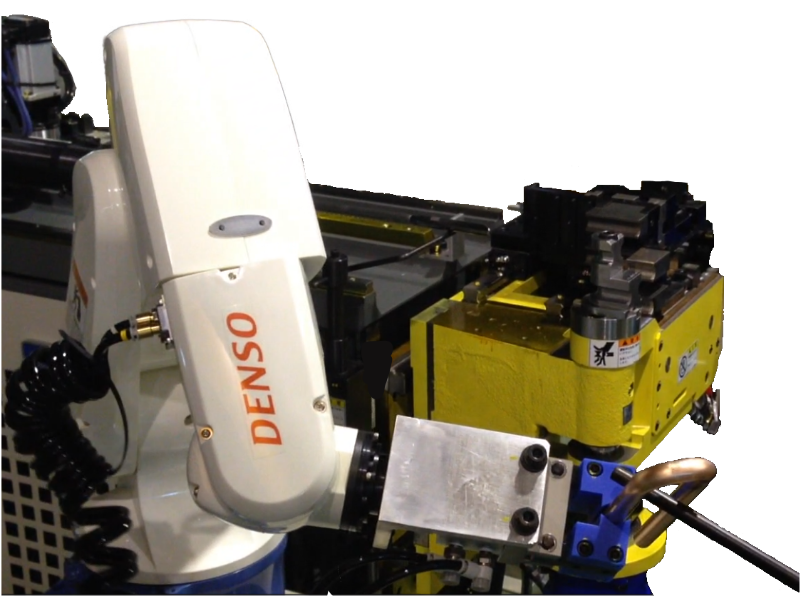

Unloader

Unloader

Typical methods include:

- Arm method

- Robot method

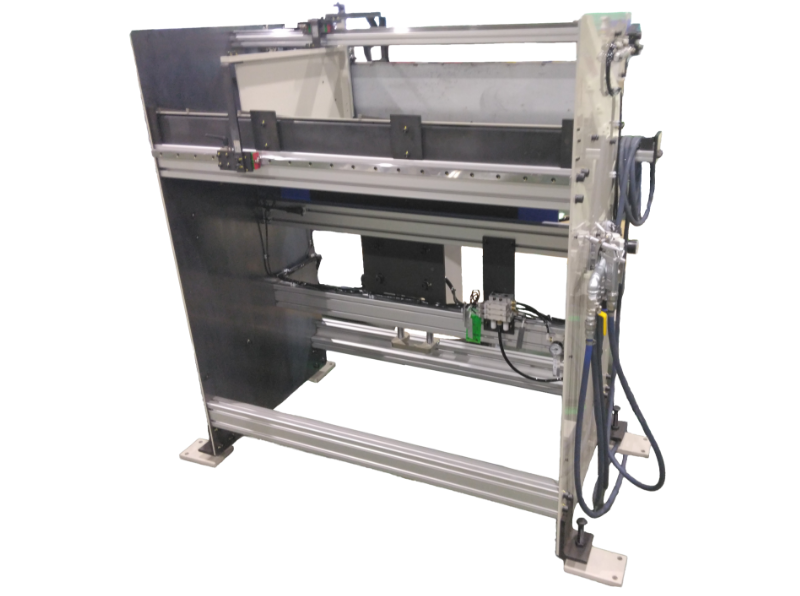

Stocker

Stocker

Typical types include:

- Bucket type

- Alignment type

- Conveyor type

- Parts-feeder type

- Vertical type

Bucket type

Alignment type

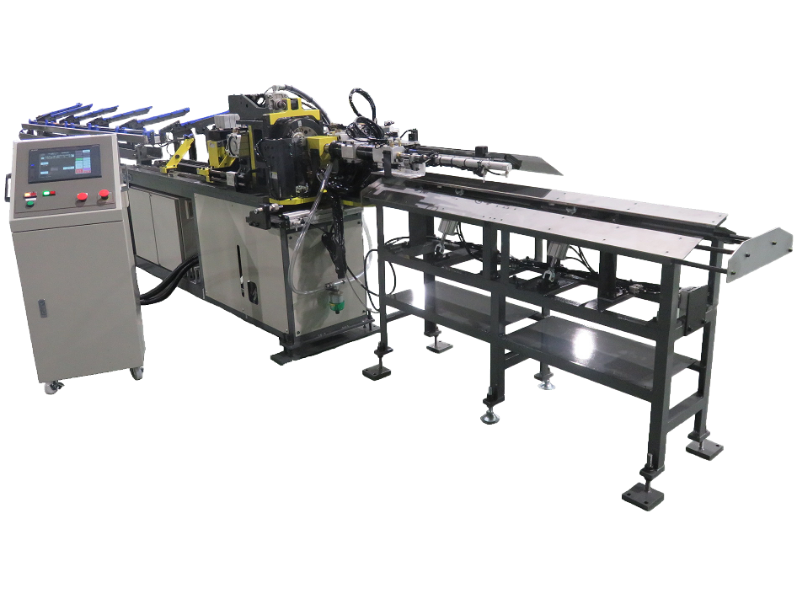

Tube Cutter

Tube Cutter

- Disk cut

- Metal-saw cut

- Chip-saw cut

GC-20 for Standard-Length Materials

OP-IM-DA1 for Coil Materials

Terminal Processing Machine

Terminal Processing Machine

- Swaging (shrinking)

- Flaring (expanding)

- Spooling

E25-2

E30-12DDV

Safety Fence

Safety Fence

Fully automated robot systems require safety fences to enclose the equipment. Based on extensive experience, we propose the optimal safety fence for customers.

Inner-Surface Seam Detection Sensor

Inner-Surface Seam Detection Sensor

Can be used for tubes, such as mirror-finish material, where exterior detection is impossible.

- Detects seam color, protrusion, and ovality using a color sensor, distance sensor, and linear sensor.

- General-purpose laser sensors often struggle to detect seam location on plated surfaces. To solve this issue, Opton developed a dedicated seam sensor—absolutely necessary for high-precision tube bending—applying their 3D optical technology.

- If the exterior cannot be detected due to plating, the inner seam is detected by the sensor.

- Rotates once in approximately 2–3 seconds; seam position is detected from one to three or more rotations’ worth of data using statistical algorithms.

- To minimize rotational vibration, the tube ends are supported by three rubber rollers.

製品についてのお問合せ

Please wait for a while until the form is shown.

Sorry, if you can not see the form even if you wait for a while, please contact Here.