DDV-Type Hydraulic Servo Pump Series

A new NC hydraulic power source replacing the servo valve

Ideal as a large hydraulic power source, offering high precision, energy efficiency, and low noise

Realizing stable operation and simplified maintenance through a simple structure

About the DDV-Type Hydraulic Servo Pump

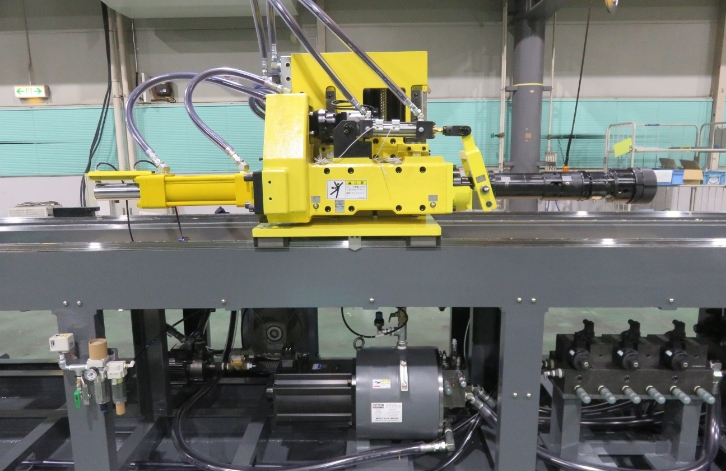

Opton Co., Ltd., building its track record as a manufacturer of CNC tube bender machines, developed a new NC hydraulic power source to improve the performance of large hydraulic CNC tube benders, replacing the conventional servo valve. This is the “DDV (Direct Drive Volume control) Type Hydraulic Servo Pump.”

As originally intended, it was installed as the NC hydraulic power source for our own large hydraulic CNC tube benders. Responding to customer requests to use it as a power source in various applications, the “DDV-Type Hydraulic Servo Pump” began to be sold as a standalone product and is now used across numerous industries, including the automotive industry.

An Ideal Power Source for Large CNC Tube Benders

AC servo motors are used as the power source for small tube benders. The performance of AC servo motors has improved to nearly perfection, and small tube benders have evolved into high-performance machines.

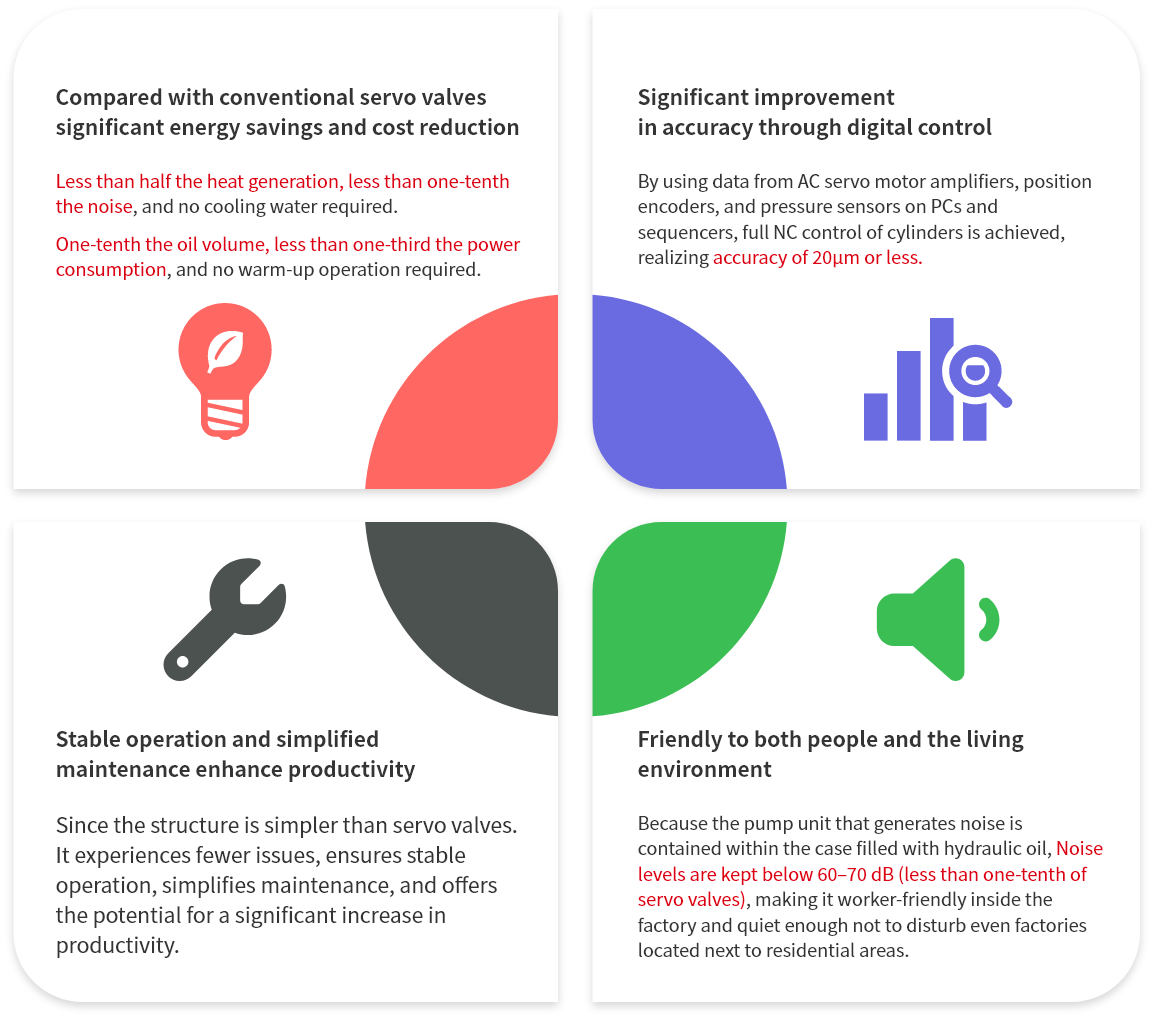

Meanwhile, large tube benders used AC servo motors and “servo valves” as power sources, but in order to achieve high performance, issues with servo valves — such as heat generation, precision instability, and high noise — needed to be addressed.

The “DDV-Type Hydraulic Servo Pump” solves the issues associated with servo valves.

Comparison: DDV-Type Hydraulic Servo Pump vs Conventional Servo Valve

| DDV-Type Hydraulic Servo Pump | Conventional Servo Valve |

|---|---|

| AC servo motor controls cylinder forward/reverse, speed, position, and torque. Uses a hybrid system with a non-leak piston pump, volume controlled by rotational speed. No throttle circuits or solenoid valves needed, simplifying tubing; compact and lightweight. |

Throttle valve type, generating frictional heat. Large fluid losses; output pressure drops to less than half of input pressure. Heat generation, precision deterioration, noise, vibration, need for large tanks, water cooling, extensive use of solenoid valves. Complex tubing, oil quality degradation, filter clogging, oil leakage issues. |

Principle of the DDV-Type Hydraulic Servo Pump

Features of the DDV-Type Hydraulic Servo Pump

Products – Product Introduction

HL-70/30

GA-3/2.0

Effects of Introduction

Feedback from users who are actually using the DDV-type hydraulic servo pump

Previously, processing was done using changeover valves and mechanical stoppers (limit switches), but it was impossible to collect or modify processing data. With the introduction of the DDV, data collection and modification became possible (NC-machine operation).

In a press-fitting machine, the condition was only pressure, causing the insertion position to vary depending on conditions. Introduction of the DDV made position control possible, improving quality.

In equipment that performed synchronous operation with servo valves, there were synchronization failures. With the introduction of the DDV, synchronization improved.

Previously, in powder-forming presses, hydraulic rams were used and needed to hold the bottom dead point, causing issues with speeding up. By introducing the DDV, controlling the bolster and making the ram crank-type, higher speeds were achieved.

In systems composed of servo motors and ball screws, the durability of the ball screw was problematic under load. By introducing the DDV and switching to a cylinder system, durability improved dramatically while maintaining equivalent precision.

Previously, a heavy-object transfer system was driven by a large hydraulic unit, which posed issues in terms of space and maintenance. With the introduction of the DDV, it became more compact, with reduced tubing and wiring, and failures were eliminated.

Previously, a heavy-object transfer system was driven by a large hydraulic unit, which posed issues in terms of space and maintenance. With the introduction of the DDV, it became more compact, with reduced tubing and wiring, and failures were eliminated.

Power consumption became one-fifth that of the conventional equipment.

Inquiries about Products

Please wait for a while until the form is shown.

Sorry, if you can not see the form even if you wait for a while, please contact Here.